Modernization

In our facilitiy we revise your used centerless grinding machine and, if necessary, upgrade it to the latest state of technical standards. The focus is on ensuring your smooth processes.

Due to our specialist knowledge, we are always able to provide you with expert advice on the possibilities of modification or modernization in the areas of mechanics and electronics/electrics.

HIRZ-KRÄMER guarantees an extension of the service life of the machines.

„You should not develop yourselves away, but upwards.“ (Nietzsche)

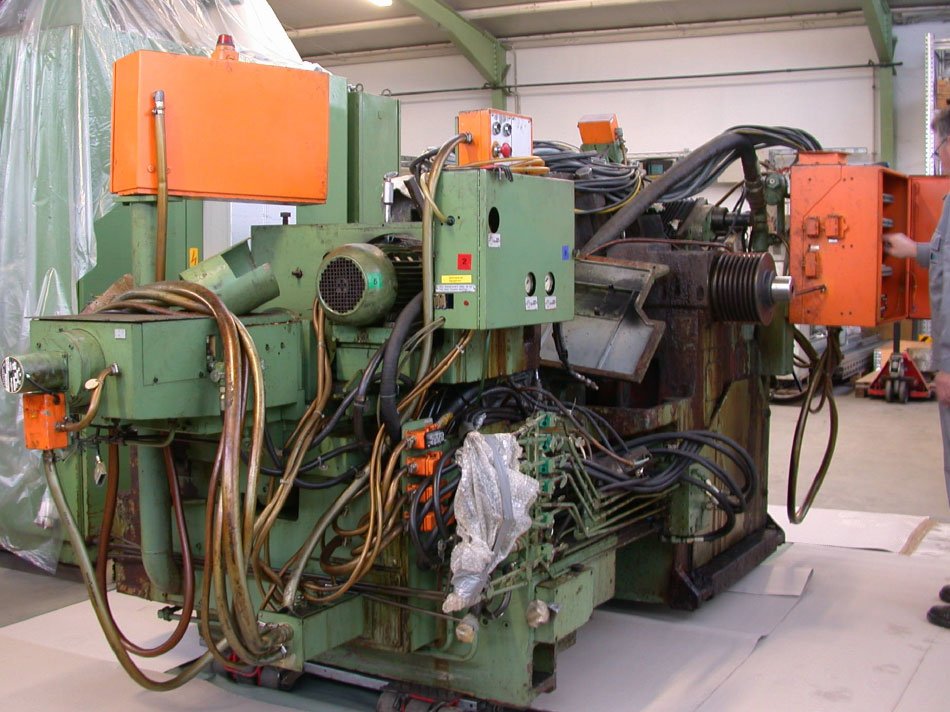

CM 3-500

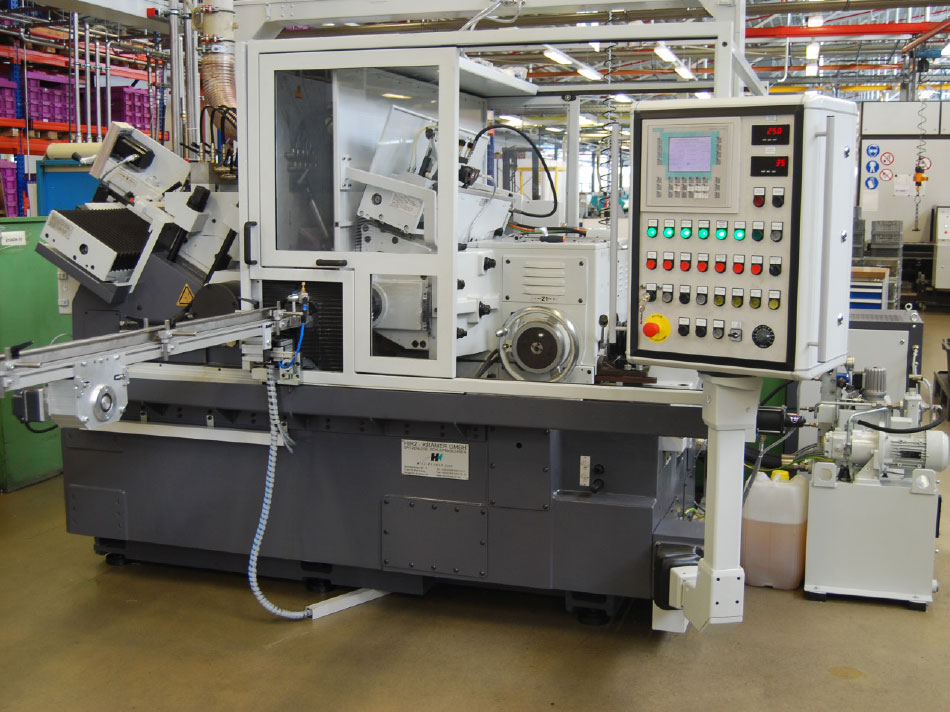

CM 3-500

old

CM 3-500

new

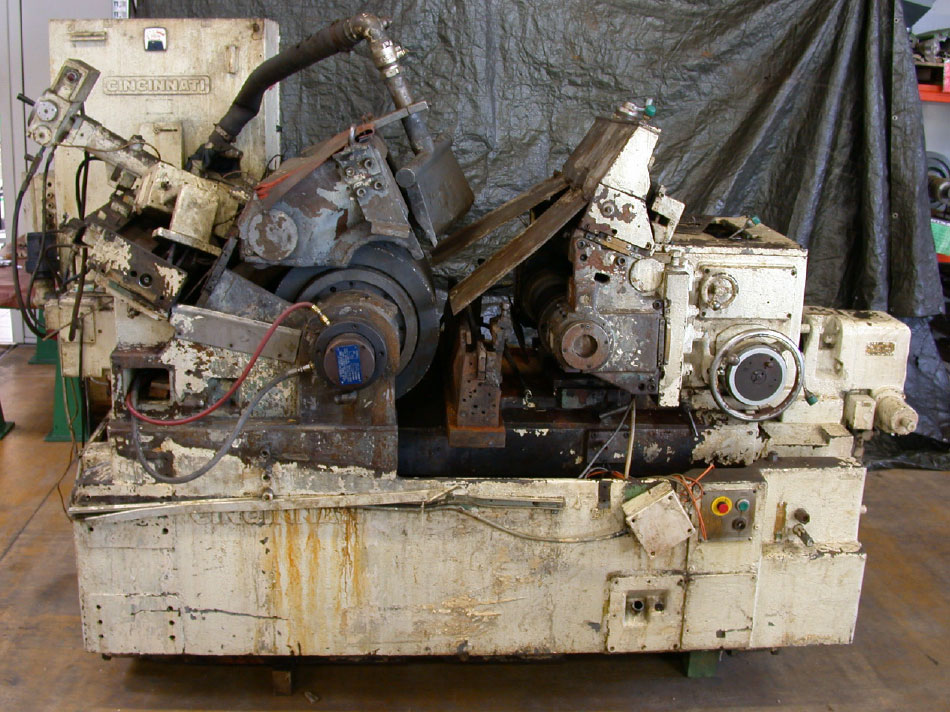

CM 340-20

old

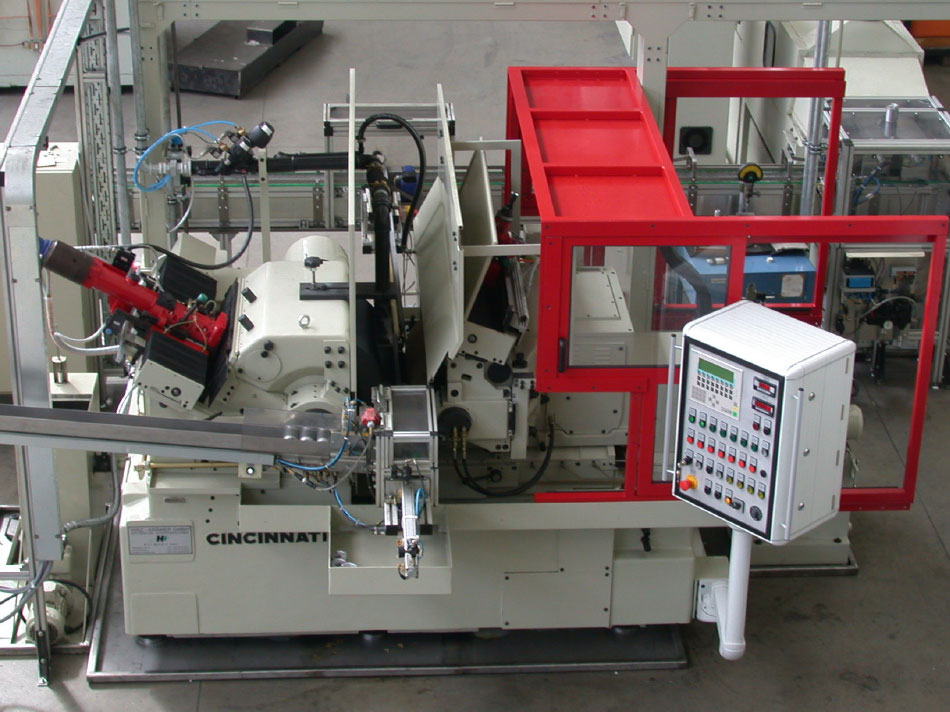

CM 340-20

new

KB M150-6

old

KB M150-6

new

Unsere Leistungen

- Modernization of infeed and compensation units as NC-axis with new mechanical drive components

- New guideway systems to achieve a higher infeed accuracy

- Modernization of grinding wheel and regulating wheel dressers to CNC dressers

- Automatic dresser program with spindle compensation

- Constant cutting speed of the grinding wheel across the entire wheel diameter, with integrated functional safety in the software/mechanics and electronics

- Integrate new loading and infeed devices (from a partner company) for infeed and thrufeed grinding

- Infeed and thrufeed grinding possible with one machine

- Construction of electrical cabinets with new components: New control panel design, new machine wiring

- Use of various Siemens controls and safety integrated plus

- Automatic balancing of grinding wheel spindle

- Freely adjustable regulating wheel speed

- New 2-component

industrial painting

- Machine guarding, safety devices